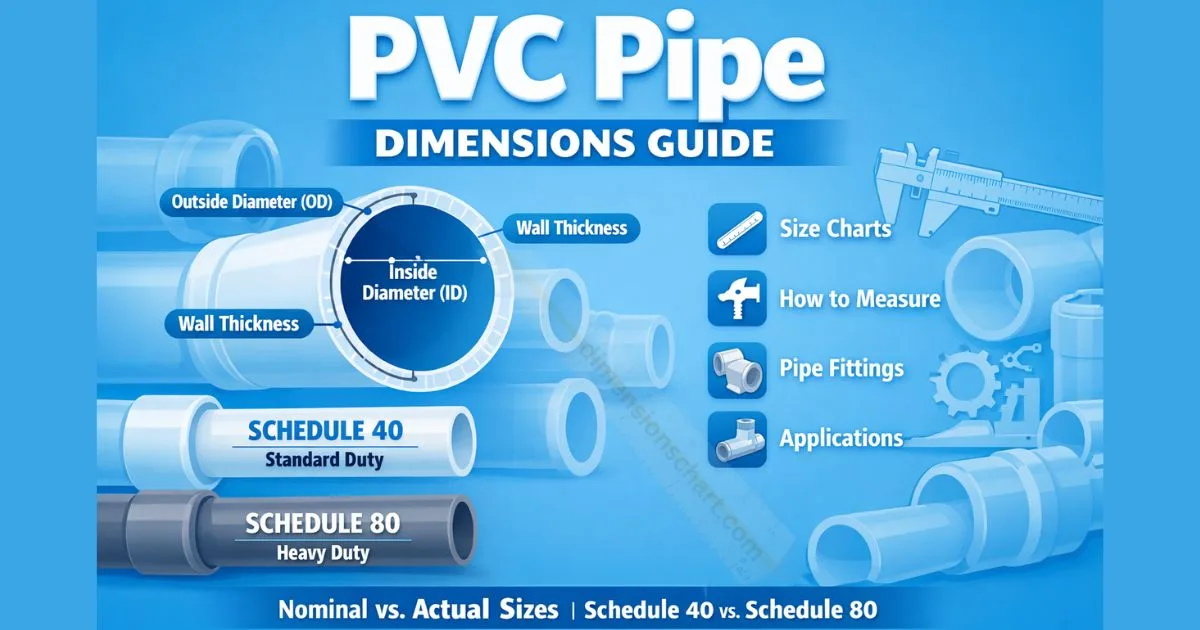

Choosing the right PVC pipe size can feel confusing when numbers don’t match what you measure. This guide breaks down every dimension you need to know.

Whether you’re working on plumbing, irrigation, or DIY projects, understanding pipe dimensions saves time and money. Let’s dive into the charts and measurements that matter.

Understanding PVC Pipe Sizing and Measurements

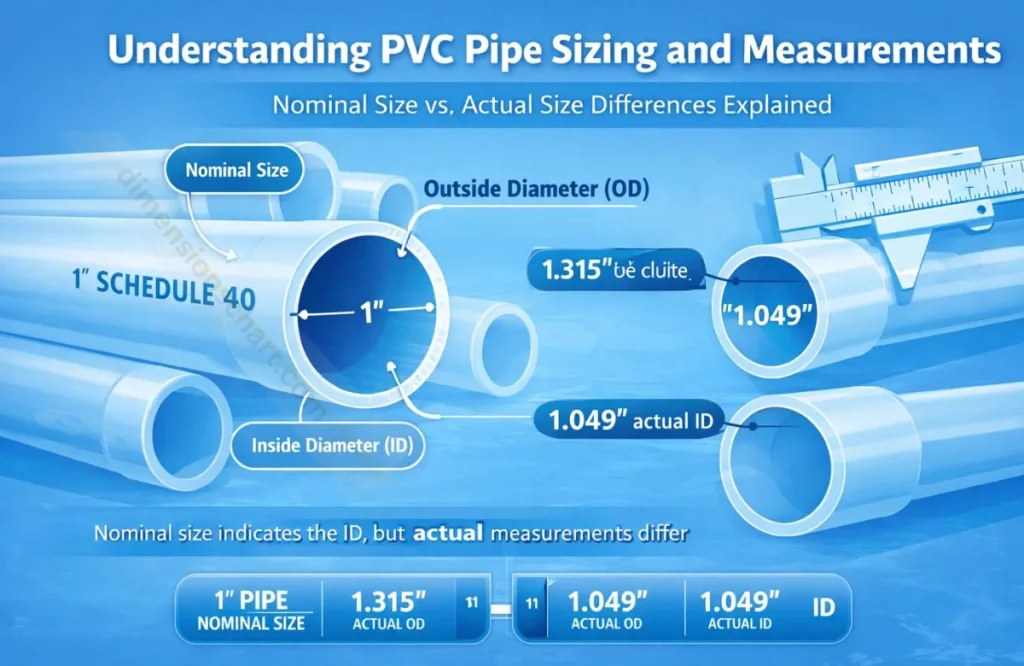

PVC pipes use a nominal sizing system that doesn’t match actual measurements. The size stamped on the pipe refers to the approximate inside diameter, not what you’ll measure with a ruler.

This system dates back to iron pipe standards from the early 1900s. All manufacturers follow these standards, making parts universally compatible across brands.

How to Read a PVC Pipe Dimensions Chart

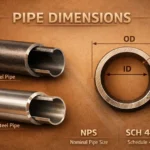

A proper dimensions chart shows three critical measurements. Outside Diameter (OD) is what you measure from edge to edge on the outside of the pipe.

Inside Diameter (ID) measures the hollow space inside where water flows. Wall thickness is the material between the inside and outside surfaces.

For example, a 1-inch Schedule 40 pipe has an OD of 1.315 inches and an ID of 1.049 inches. The wall measures0.133 inches thick.

The Difference Between Nominal and Actual Pipe Sizes

Nominal size is the name we call the pipe, like “1-inch” or “2-inch.” The actual size refers to the real measurements you can verify with calipers or a ruler.

A 1-inch nominal pipe actually measures 1.315 inches on the outside. This standardization ensures all1-inch fittings fit all 1-inch pipes, regardless of manufacturer.

The ID changes between schedules, but the OD stays the same. This allows different schedule fittings to connect to the same nominal size pipe.

Schedule 40 PVC Pipe Dimensions Chart

Schedule 40 PVC is the most common type for residential and light commercial use. The white-colored pipe handles standard pressure applications up to 280 PSI for smaller sizes.

Here’s what you need to know about Schedule 40 dimensions:

Complete Size Specifications

40 PVC Pipe Dimensions Chart

| Nominal Size | Outside Diameter (inches) |

Inside Diameter (inches) |

Wall Thickness (inches) |

Pressure Rating (at 73°F) |

|---|---|---|---|---|

| 1/2″ | 0.840″ | 0.622″ | 0.109″ | 600 PSI |

| 3/4″ | 1.050″ | 0.824″ | 0.113″ | 480 PSI |

| 1″ | 1.315″ | 1.049″ | 0.133″ | 450 PSI |

| 1-1/4″ | 1.660″ | 1.380″ | 0.140″ | 370 PSI |

| 1-1/2″ | 1.900″ | 1.610″ | 0.145″ | 330 PSI |

| 2″ | 2.375″ | 2.067″ | 0.154″ | 280 PSI |

| 3″ | 3.500″ | 3.068″ | 0.216″ | 260 PSI |

| 4″ | 4.500″ | 4.026″ | 0.237″ | 220 PSI |

| 6″ | 6.625″ | 6.065″ | 0.280″ | 180 PSI |

Note: Pressure ratings apply at 73°F water temperature. Higher temperatures significantly reduce capacity.

Schedule 40 applications include drainage systems, residential water lines, and irrigation networks. It’s also popular for DIY furniture projects due to easy cutting and assembly.

Schedule 80 PVC Pipe Dimensions Chart

Schedule 80 PVC features thicker walls and higher pressure ratings. The gray-colored pipe withstands more stress and is required by code for certain commercial installations.

The thicker walls mean smaller inside diameters compared to Schedule 40. This reduces flow capacity but increases strength and durability.

Complete Size Specifications and Ratings

80 PVC Pipe Dimensions Chart

| Nominal Size | Outside Diameter (inches) |

Inside Diameter (inches) |

Wall Thickness (inches) |

Pressure Rating (at 73°F) |

|---|---|---|---|---|

| 1/2″ | 0.840″ | 0.546″ | 0.147″ | 850 PSI |

| 3/4″ | 1.050″ | 0.742″ | 0.154″ | 690 PSI |

| 1″ | 1.315″ | 0.957″ | 0.179″ | 630 PSI |

| 1-1/4″ | 1.660″ | 1.278″ | 0.191″ | 520 PSI |

| 1-1/2″ | 1.900″ | 1.500″ | 0.200″ | 470 PSI |

| 2″ | 2.375″ | 1.939″ | 0.218″ | 400 PSI |

| 3″ | 3.500″ | 2.900″ | 0.300″ | 370 PSI |

| 4″ | 4.500″ | 3.826″ | 0.337″ | 320 PSI |

| 6″ | 6.625″ | 5.761″ | 0.432″ | 280 PSI |

Note: Outside diameter matches Schedule 40 exactly. Pressure ratings at 73°F; higher temperatures reduce capacity.

Notice the outside diameter matches Schedule 40 exactly. This allows you to use Schedule 80 fittings on Schedule 40 pipe when needed, though mixing isn’t recommended for pressure applications.

Schedule 80 uses include chemical processing, high-pressure water systems, and industrial applications. Many building codes require it for compressed air lines.

How to Measure PVC Pipe Correctly

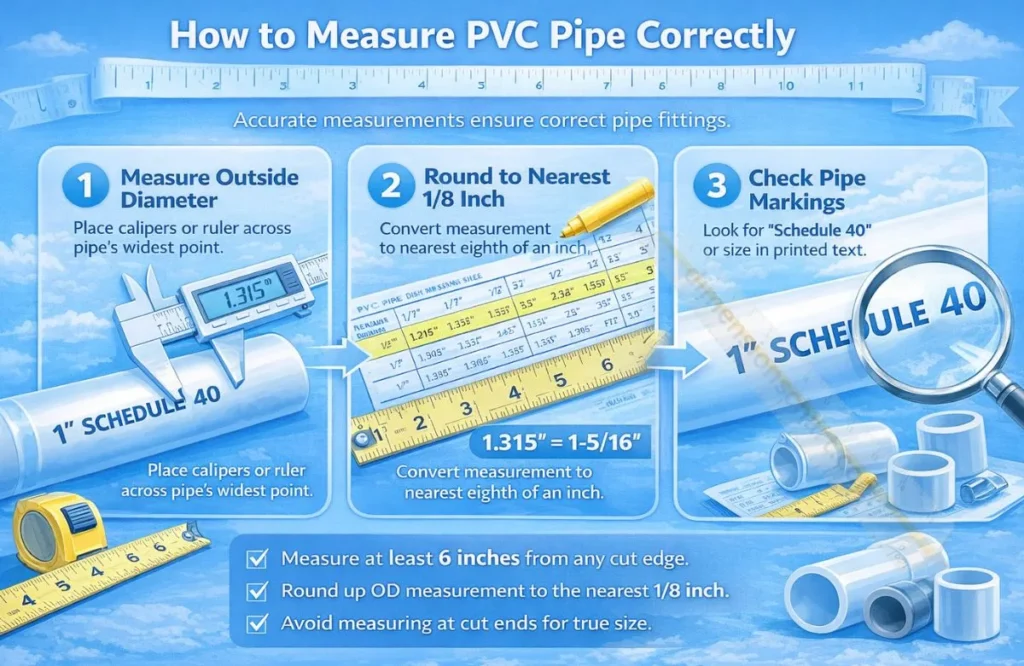

Wrong measurements lead to buying incorrect fittings. Measuring PVC pipe requires understanding what you’re actually measuring.

Most beginners measure the outside and get confused when fittings don’t match. Follow these steps for accurate results every time.

Step-by-Step Measurement Guide

First, measure the outside diameter with calipers or a ruler. Place the tool across the widest part of the pipe’s circular edge.

Round your measurement to the nearest 1/8 inch. Then match that number to the OD column in the charts above.

For a 1.315-inch OD measurement, you have 1-inch nominal pipe. For 2.375 inches, that’s 2-inch nominal size.

Inside diameter is harder to measure accurately. It’s easier to identify pipe by OD and check the schedule marking printed on the pipe itself.

Look for stamped text showing “Schedule 40” or “Sch 80” along with the nominal size. This eliminates guesswork completely.

Common mistakes include measuring at pipe ends where cuts aren’t perfectly round. Always measure at least 6 inches from any cut edge for accuracy.

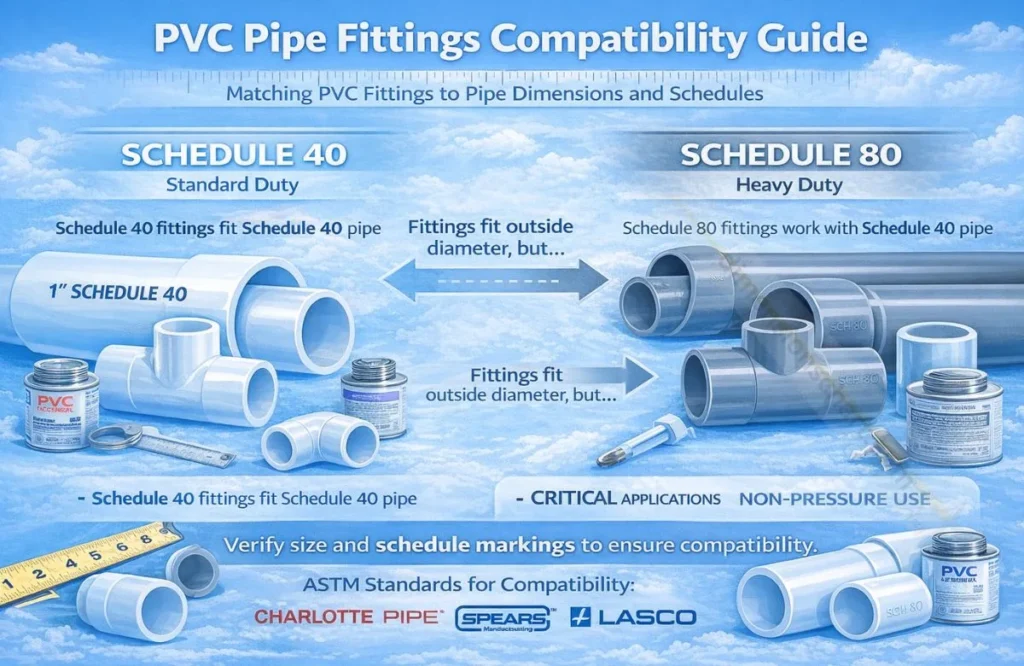

PVC Pipe Fittings Compatibility Guide

PVC fittings must match both the nominal size and schedule for proper connections. A 1-inch Schedule 40 tee only fits 1-inch Schedule 40 pipe perfectly.

Since outside diameters match across schedules, fittings can physically connect. However, pressure ratings and code compliance may prohibit mixing schedules in critical applications.

Matching Fittings to Pipe Dimensions

All Schedule 40 fittings work with Schedule 40 pipe of the same nominal size. The socket depth and diameter are engineered for exact fits with proper cement application.

Schedule 80 fittings have the same external socket size but thicker walls. They fit Schedule 40 pipe externally but create weaker joints due to different wall thicknesses.

Professional plumbers avoid mixing schedules in pressure systems. For non-pressure applications like furniture or structures, mixing is acceptable.

Manufacturer variations are minimal due to ASTM standards. Charlotte Pipe, Spears Manufacturing, and Lasco products all interchange within the same schedule and size.

When exact measurements matter for specialized projects, request specification sheets from manufacturers. Most provide detailed CAD drawings with tolerances.

Conclusion

Understanding PVC pipe dimensions prevents costly mistakes and ensures proper system performance. Always verify both nominal size and schedule before purchasing materials.

Use these dimension charts as your go-to reference for any project. Measure carefully, match schedules appropriately, and follow manufacturer guidelines for best results.

FAQs

What do the numbers in PVC pipe sizes mean?

The numbers represent the nominal inside diameter in inches. A “2-inch pipe” has roughly a 2-inch opening inside, though actual measurements vary by schedule. This naming system comes from historical iron pipe standards.

The actual inside diameter of 2-inch Schedule 40 is 2.067 inches. For Schedule 80, it’s 1.939 inches due to thicker walls.

Can I use Schedule 40 and Schedule 80 fittings together?

You can physically connect them since outside diameters match, but it’s not recommended for pressure applications. The different wall thicknesses create uneven stress points that can fail under pressure.

For non-pressure projects like furniture or plant supports, mixing schedules works fine. Always follow local building codes for plumbing installations.

How do I know what size PVC pipe I have?

Check the printed markings on the pipe showing nominal size and schedule. If markings are worn off, measure the outside diameter and compare to standard charts.

A 1.315-inch OD means 1-inch nominal pipe. A 2.375-inch OD indicates 2-inch pipe, regardless of schedule.

What is the difference between nominal size and actual size?

Nominal size is the standardized name like “1-inch” or “3/4-inch.” Actual size refers to the real measurements you can verify with tools.

This system ensures universal compatibility. Every 1-inch fitting fits every 1-inch pipe because the actual dimensions are standardized industry-wide.

Are PVC pipe dimensions the same across all manufacturers?

Yes, all manufacturers follow ASTM D1785 standards for Schedule 40 and ASTM D2665 for Schedule 80. Outside diameters, wall thicknesses, and pressure ratings are identical.

Spears, Charlotte Pipe, Lasco, and other brands interchange perfectly. Minor variations exist in fitting socket depths, but these stay within acceptable tolerances.

More Dimensions:

Burhan Ali is the founder and author of DimensionsChart.com, providing accurate size charts, measurements, and guides for smarter buying decisions.